Kontakt

Vi ger personlig service från måndag till fredag, från 8:00 till 17:00. Via den här länken hittar du kontaktpersonen för din region.

Huvudkontor Wolfurt

+43 5574 6706-0

Varukorg {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artikel Ändra varukorg

Anmärkning

| Bild | Artikel | St | Enhetspris | Totalpris | Totalt pris inklusive rabatt | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Kunder

- Mould making

- Die making

- Maskin- och fixturbygge

- Konstruktörer

- Formsprutare

- Produkter

- Företag

- Karriär

- Service

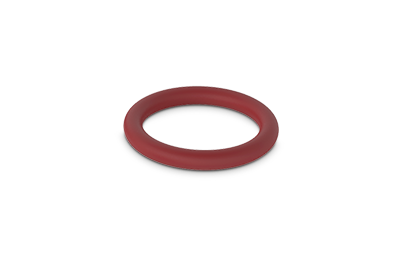

O-ring seals - in perfect shape, part 1

Publicerad den: 30.06.2020

General information and selection

In this first part, we explain the different sealing types, installation options and materials of O-rings especially for mould making. O-ring seals are C-parts which cost only a few cents apiece. However, if an O-ring seal does not seal properly, it may result in downtimes and lead to high costs. To prevent this, in addition to the selection of the correct material, the design, the production of the O-ring groove and the correct installation, removal and maintenance of the O-ring seals are all important factors.

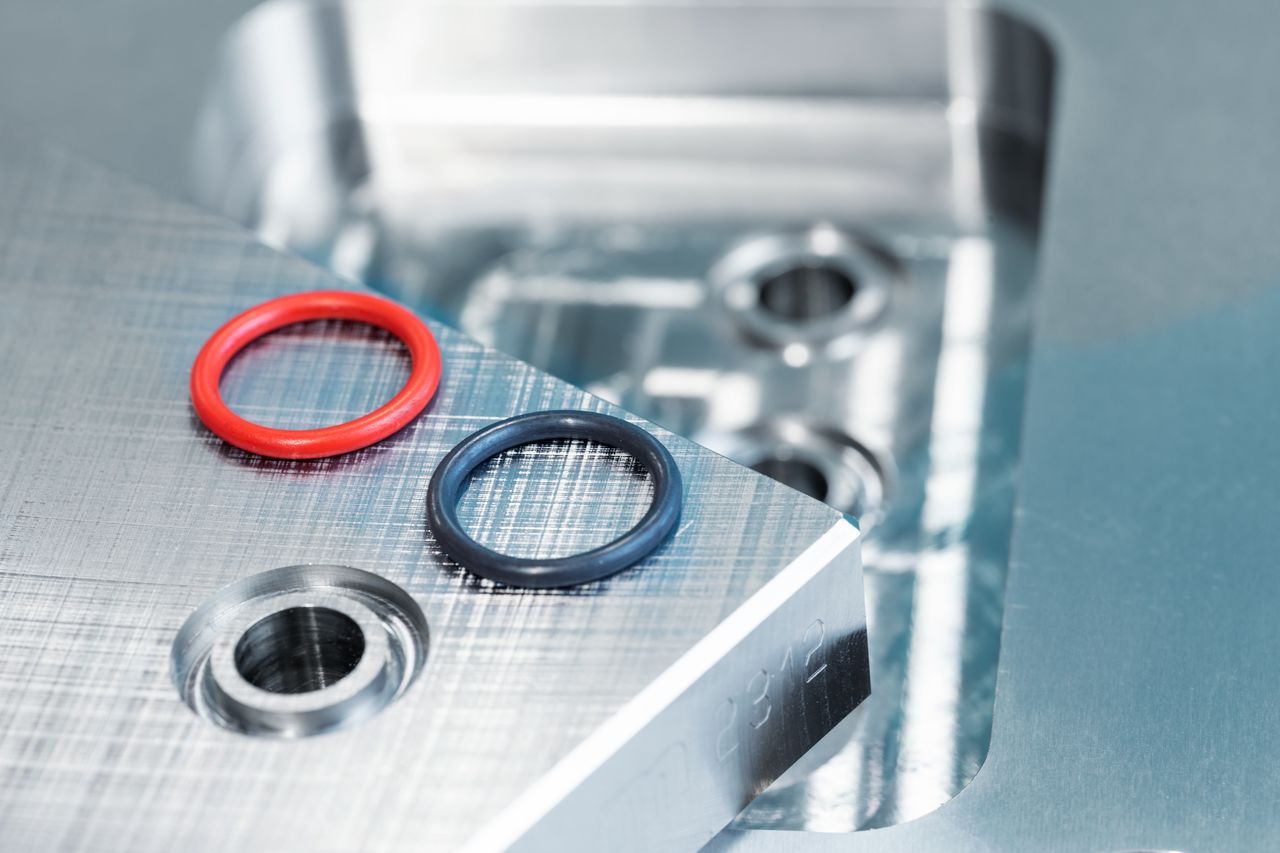

Use of O-ring seals

O-ring seals are mainly used in mould making to seal cooling holes used at plate transition or for components such as fountains and deflection elements. But O-ring seals can also be found in other components such as hydraulic cylinders and oil ports.

Dynamic and static sealing

A basic distinction is made between dynamic and static sealing. A dynamic seal is when the seal is created between components that move towards each other. O-ring seals are the optimum technical solution for dynamic sealing only in exceptional cases. For static sealing there is no movement between the components.

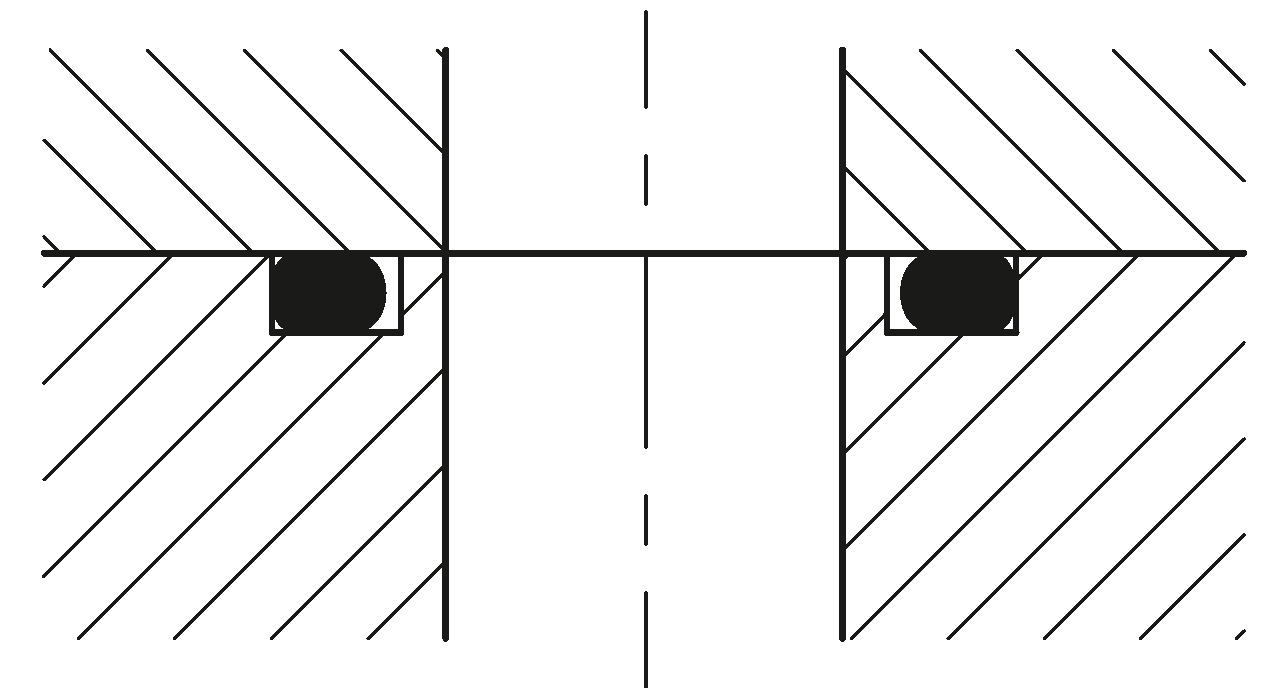

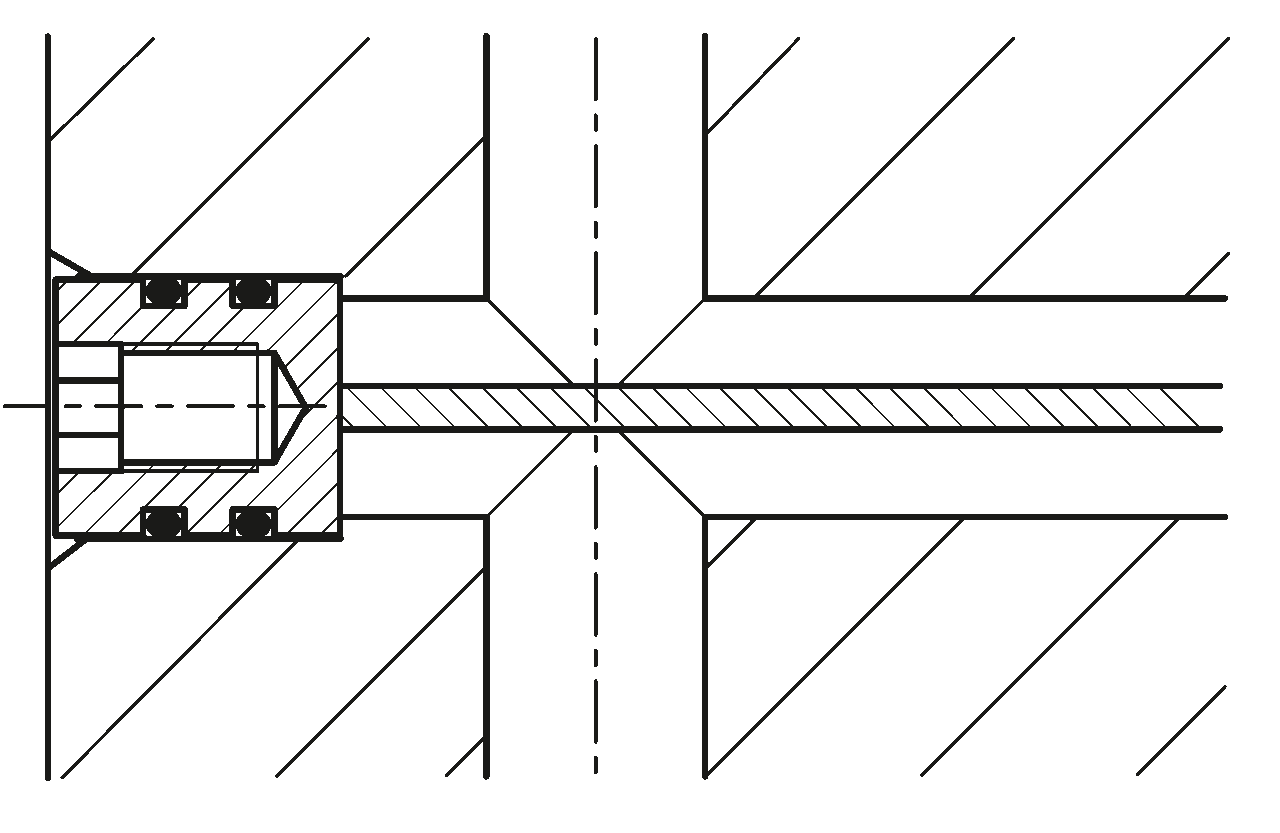

Axial and radial installation

The following figures compare axial and radial installation

Axial installation

Radial installation

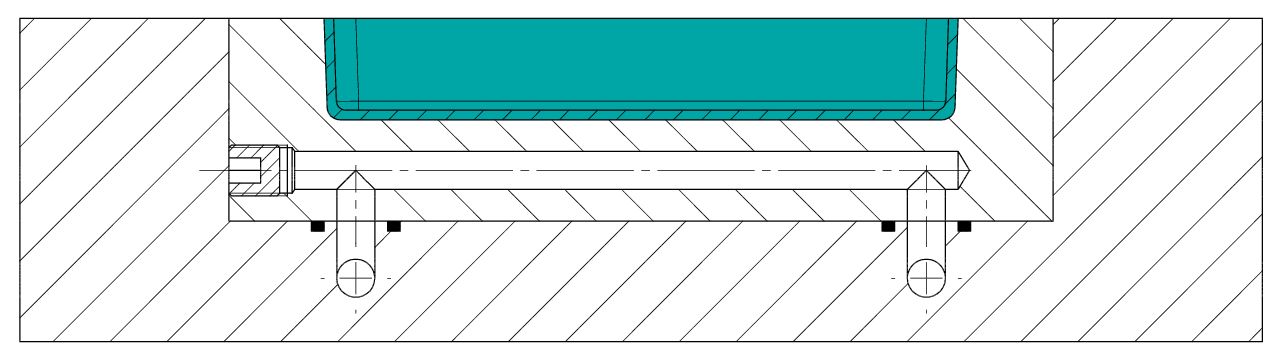

In mould making, mainly static sealing is used with mostly axial installation. An example of this is the transition of the cooling holes from the cavity plate to the inserts.

Example of a mould insert

O-ring seal materials in mould making

The O-ring seals used in mould making are made of the material fluororubber - shortened to FKM, or FKM plus. FKM is generally very resistant to a variety of mediums and chemicals.

The selection of O-ring seal material depends mainly on the operating temperature. The usual FKM materials are used at water temperatures up to 100°C. If these were operated at water temperatures above 100°C they would harden, lose their elasticity and thus the pretension for the sealing effect. That’s why the special high-temperature O-ring seals made of the material FKM plus were developed for water temperatures over 100°C.

Företag

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2023 Meusburger

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]