Different options

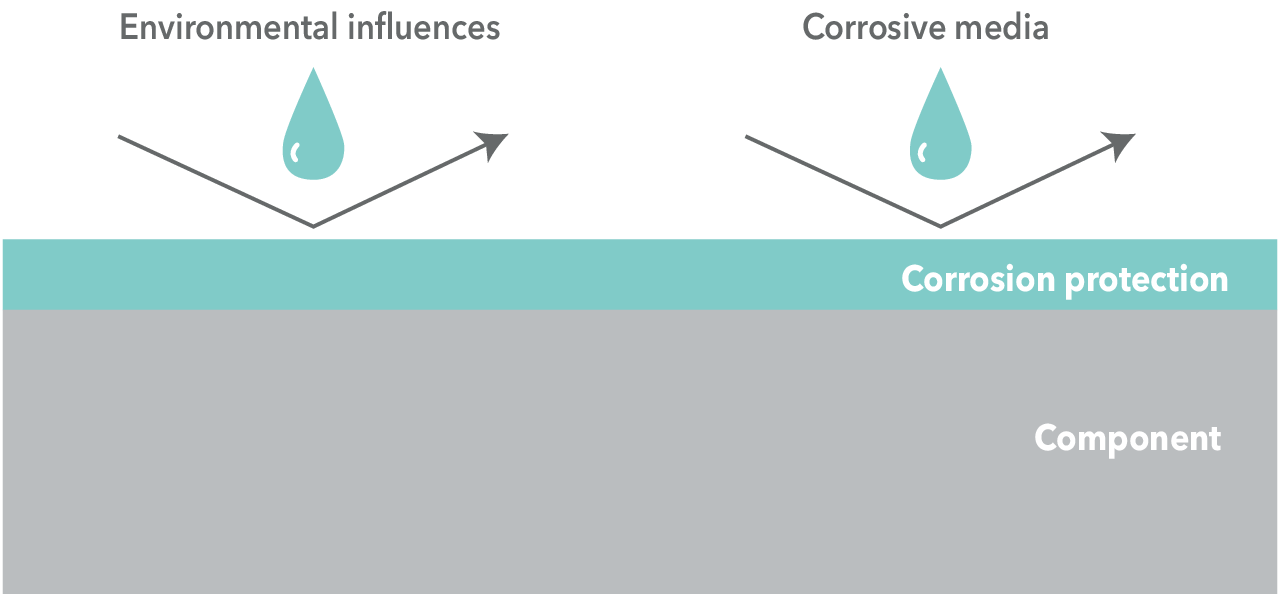

Permanent surface coatings such as lacquers, galvanic top coating and temporary coatings of greases, oils, waxes and similar substances are popular. However, in the end they all offer the same: They are meant to properly coat the component to shield it from environmental influences and corrosive media.

PRETREATMENT OF SURFACES

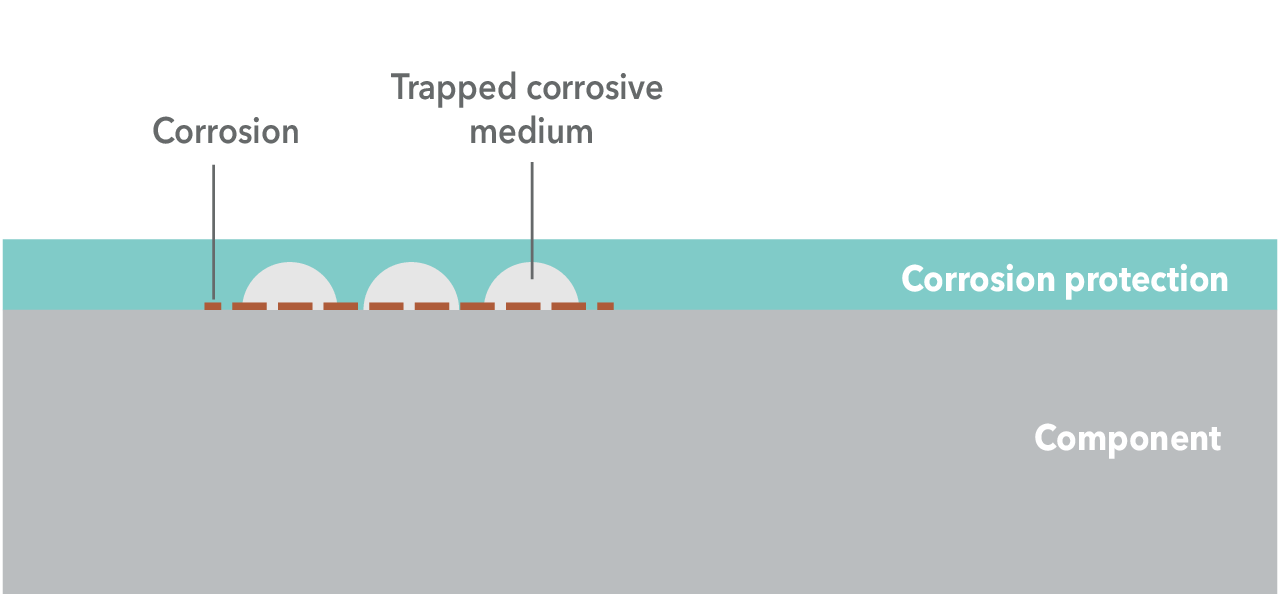

A clean base is half the battle – this goes for adhesive bonding and lubricating as well as corrosion protection. A clean base not only guarantees the best possible adhesive strength, but also that no corrosive residues are trapped between the anticorrosive and the component.

Suitable cleaners

APPLICATION OF CORROSION PROTECTION

This is what you must bear in mind when applying anticorrosives:

- Closed layer

- Sufficient coating thickness

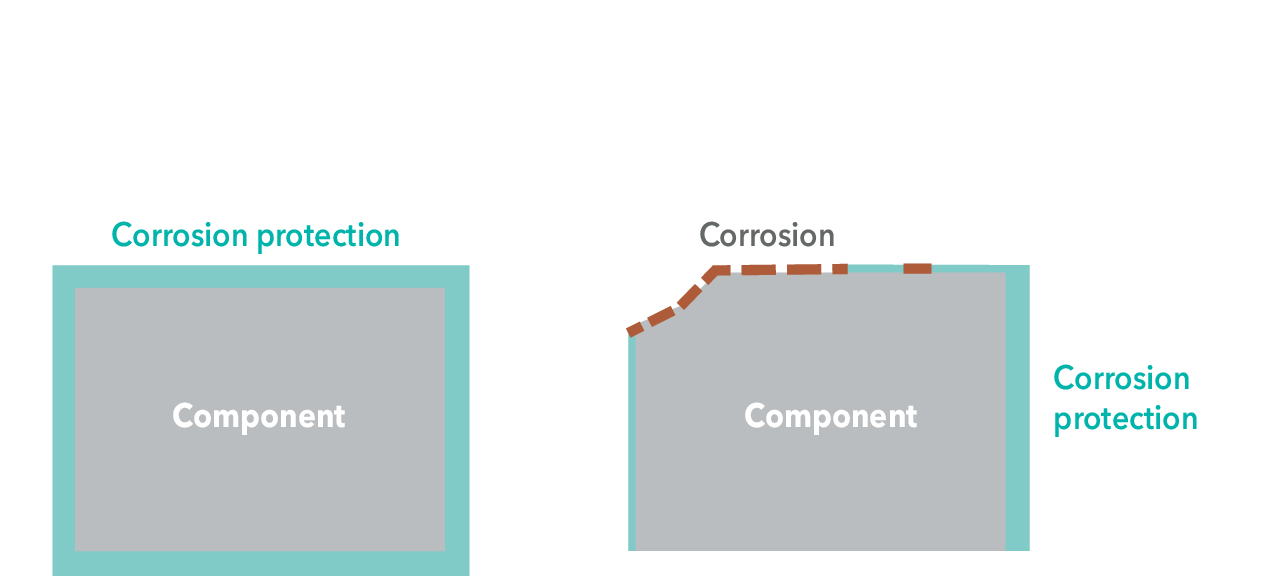

A closed layer prevents contact with environmental influences and all types of corrosive media. A greater thickness of coating offers greater resistance to material removal and penetration of the corrosion protection. It improves the protection – as they say ‘the thicker the better’.

Which anticorrosive is right?

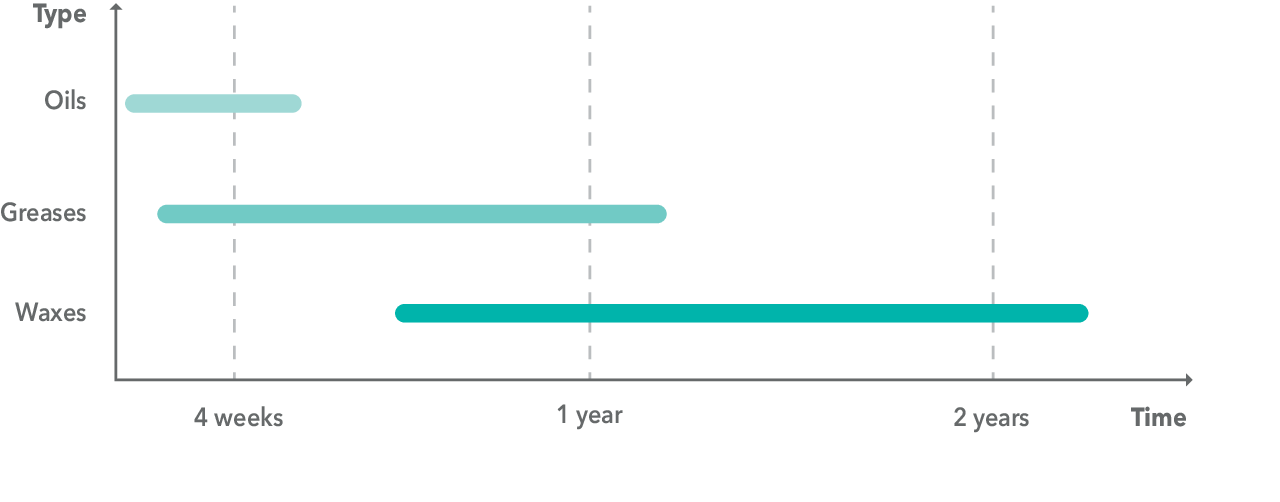

In mould and die making, corrosion protection greases, waxes, and oils are most common. Each variant has different advantages and disadvantages.

Oils

- Easy to use

- For very short and straightforward storage times

Our oils are very suitable for the regular maintenance and short-term protection of machine parts, for example, when they are used on our GMT 6000 cutting and grinding machine or our H 4062 assembly table . Thin oils can easily remain on the parts even during commissioning.

Greases

- For short-term corrosion protection

- Leaves behind a thin oil or grease-like film

- Can usually remain on the part during commissioning or can be removed again very easily

A very important characteristic of corrosion protection greases in mould and die making is penetration. This is usually very low, which means that high-value lubrication points such as ejectors and slides are not contaminated with the corrosion protection. Thus, our greases are perfect for cavity protection.

Waxes

- For medium-term storage times

- Good protection even under the most adverse conditions (e.g. overseas transport or wire EDM)

- Must be removed before commissioning

Removal is somewhat more involved than with the greasy alternatives. But with the right cleaner this is not a problem. In addition, the low viscosity waxes penetrate very well into all crevices, preserving moulds very well from the outside, for example. But make sure that the wax does not reach lubrication points and contaminate them.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]